Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

This article provides a detailed introduction to the concept, application areas, selection guidelines, and development trends of electronic Connectors.

Electronic connectors are an indispensable component of electronic devices, with fast and reliable signal transmission characteristics, which can significantly improve the operational performance and stability of equipment.

1. Overview Electronic connectors play a crucial role in the field of modern electronic information technology. Its main function is to connect various electronic components, such as circuit boards, computers, smartphones, televisions, as well as display screens, cameras, etc., to achieve rapid and reliable electronic signal transmission. Choosing appropriate electronic connectors, combined with scientific and reasonable manufacturing processes, can help improve equipment performance and reliability.

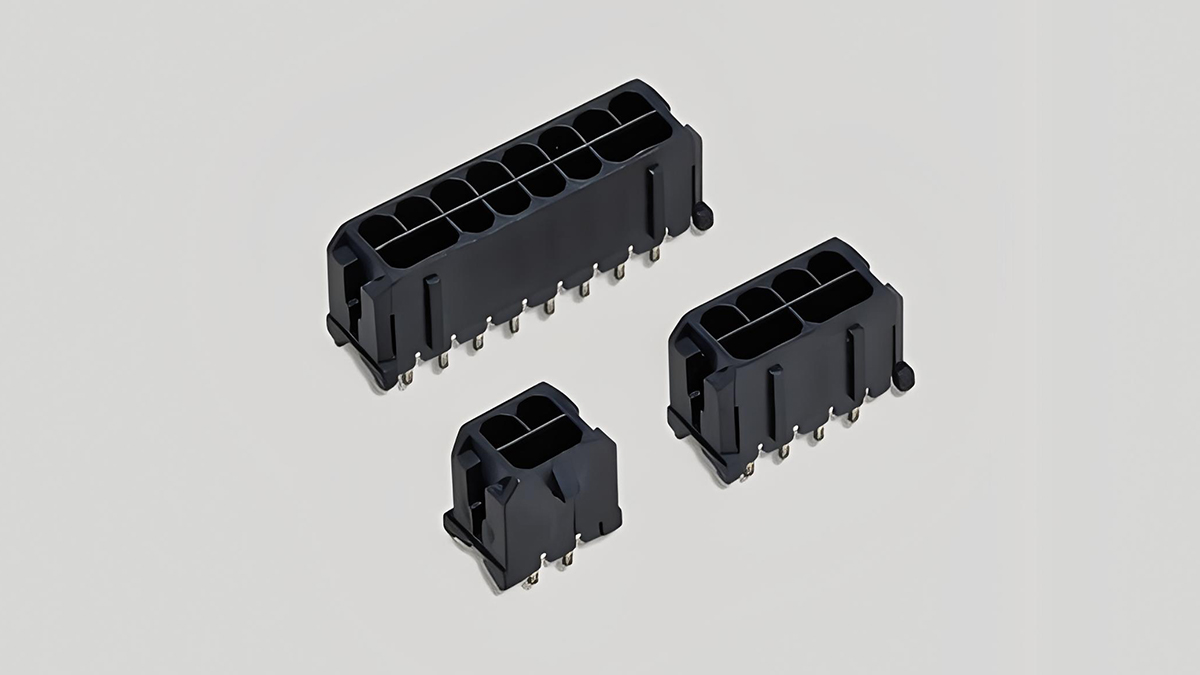

2. Function and Scope of Application Electronic connectors are usually composed of metal or plastic parts, such as pins, sockets, casings, shielding covers, etc. Internally, there are pins or pins that can be used for electrical connection, thus completing signal transmission. Due to differences in usage scenarios and requirements, electronic connectors exhibit diverse appearance structures and connection methods. Specifically, it can be understood and applied from the following categories:

(1) Circular connectors - due to their standardized circular shape, they are often used in high-power, high-voltage, and pulse electrical applications.

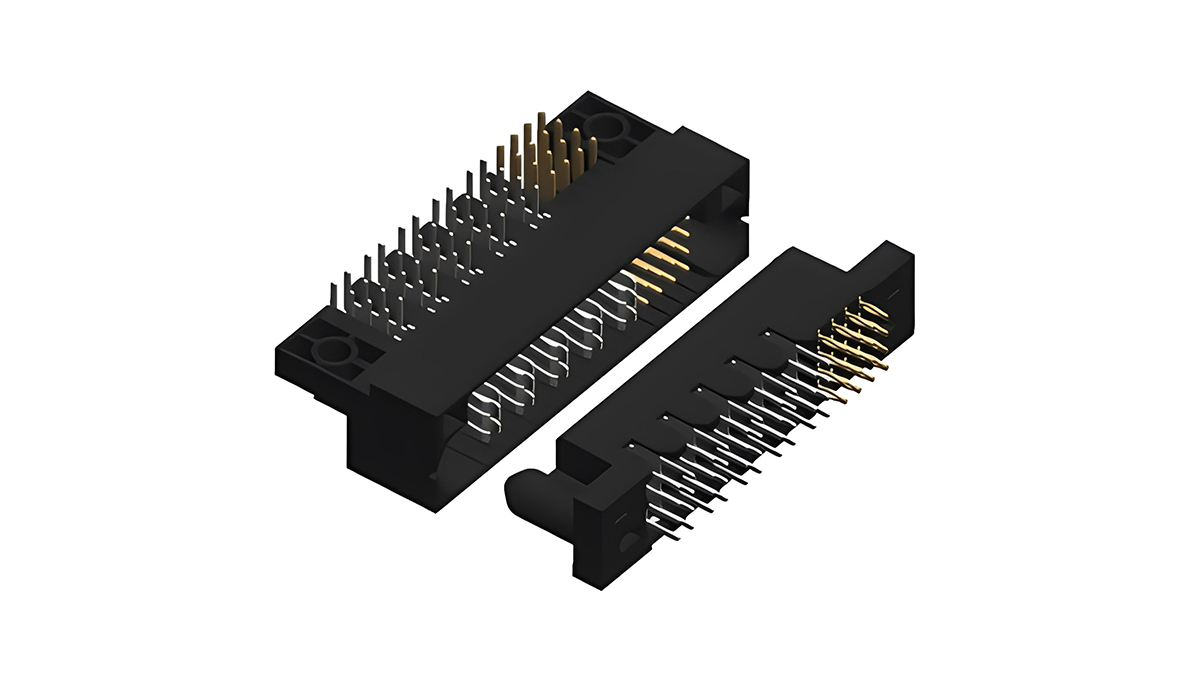

(2) Rectangular connector - characterized by rectangular and elongated shapes, suitable for various electrical systems, including anti-interference filters and other equipment.

(3) Linear connector - designed in linear form, suitable for circuit board installation or parallel connection scenarios with circuit boards.

(4) Curved connectors - Curved shapes are suitable for complex installation environments, with the most typical being Type 1 special structures.

3. Connector selection The selection of electronic connectors should fully consider various factors such as working frequency, electrical requirements, environmental conditions, external structure, and installation method. For example, low-frequency connectors are usually suitable for processing low-frequency signals, while high-frequency connectors are suitable for high-speed transmission of higher frequency signals. In addition, according to different needs, electronic connectors can be divided into more than 100 types, such as round head connectors, pin connectors, USB Type C connectors, and so on. Choosing a solution that meets the actual application needs to ensure smooth and stable connections is crucial for improving equipment operational efficiency.

4. Connector manufacturing Manufacturing electronic connectors requires multiple key technological processes, including injection molding, stamping mold production, 3D design and mold opening, and electroplating. Each connector manufacturer needs to have advanced and sophisticated manufacturing processes as well as stable and mature production processes to ensure the performance and quality of the connectors produced. Once problems such as poor contact, insulation failure, or loose fixation occur, manufacturers also need to have strong technical capabilities to carry out relevant inspection and repair work.

5. Future development trends It is expected that the focus of future Electronic Connector development will be concentrated in:

(1) Lightweight and miniaturized - With the increasing miniaturization of electronic products, the size of connectors is decreasing.

(2) High speed informatization - With the development of digital communication technology, the demand for high-speed transmission of higher data bandwidth and transmission speed will continue to rise.

(3) Highly intelligent - connectors should meet high-end intelligent requirements, such as automatically identifying different device connections and real-time monitoring of connection conditions.

(4) Durable and sturdy - Electronic connectors need to have stronger resistance to different environmental characteristics, that is, to maintain stable and long-lasting performance under harsh environmental conditions such as high temperature, low temperature, and even extreme humidity.

6. Summary As a core component of electronic devices, electronic connectors are undoubtedly closely related to their operational performance and stability.

In the future, with further technological innovation and progress, the types and application fields of electronic connectors will also continue to expand and grow. Team members need to closely monitor industry trends, continuously research and explore cutting-edge technologies, and use a scientific and rigorous attitude to carefully polish product processes, in order to provide customers with stable, efficient, and cost-effective connector products!

LET'S GET IN TOUCH

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.