When we talk about the interconnection of electronic devices, we cannot ignore the importance of Industrial connectors. This document aims to introduce the functions, types, and selection considerations of industrial Connectors in electrical interconnection.

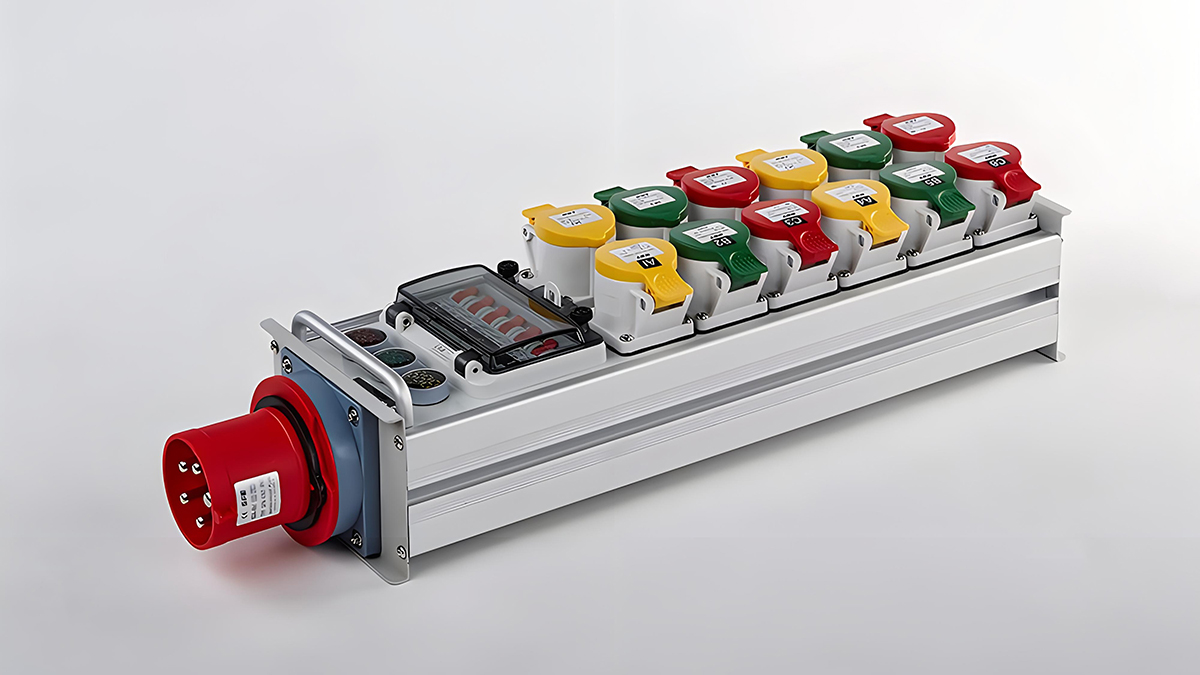

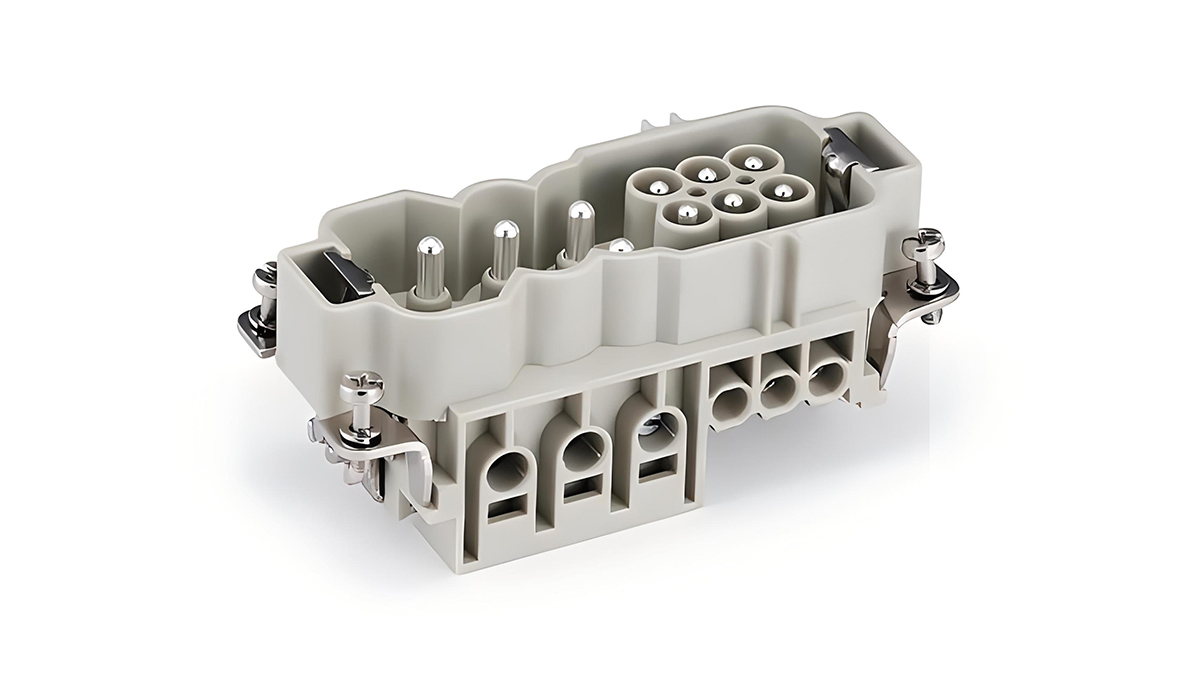

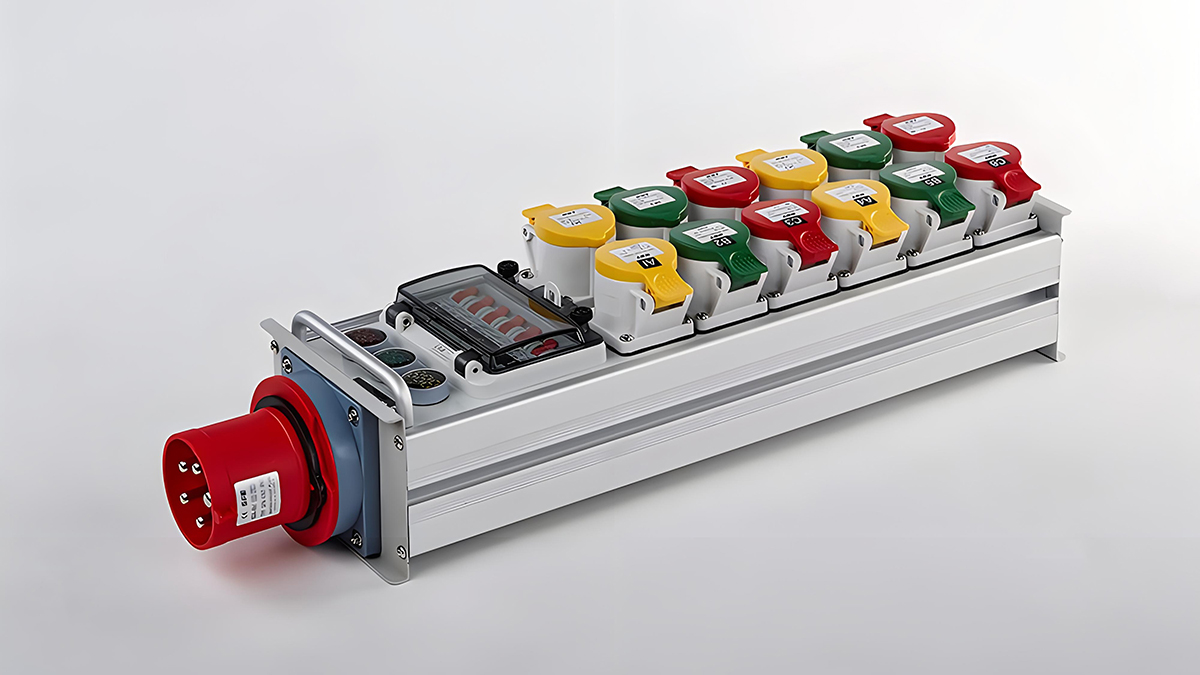

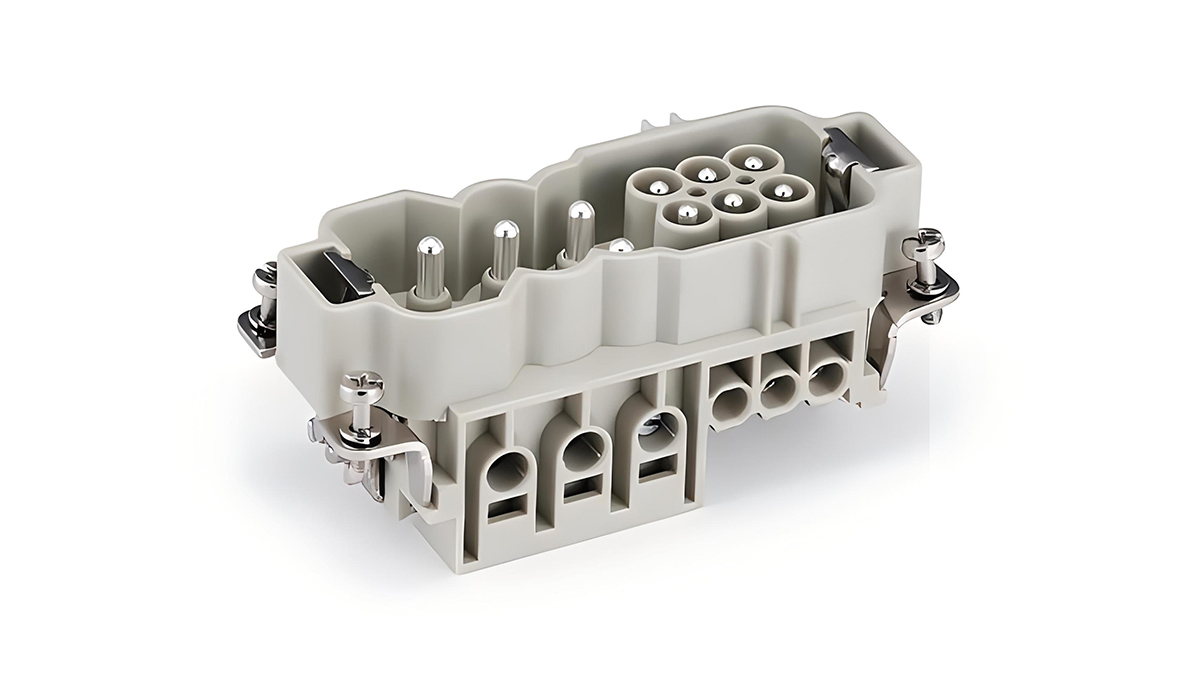

Industrial connectors are industrial components specifically designed for electrical connections between various electronic and electrical equipment. It is usually made of metal or plastic materials, with both ends constructed as matching male and female terminals. There are many types of connectors, such as threaded connectors, bayonet connectors, inline connectors, and junction box connectors, etc. Each connection method has its own advantages and is suitable for different places.

Common industrial connectors include power connectors, signal connectors, data connectors, radio frequency (RF) connectors, and so on. The power connector connects the power supply device to the electrical device; Signal connectors are responsible for transmitting signals; The data connector is mainly responsible for transmitting data and some communication protocols.

When selecting industrial connectors, factors to consider include electrical performance parameters, dimensions, material properties and protection levels, supported communication specifications, brand awareness, and product quality.

Industrial connectors are everywhere, whether it's electronic or electrical equipment, even airplanes and satellites, they cannot be separated from it. It can help build electrical systems and achieve rapid transmission and efficient conversion of data, signals, and electricity. Overall, industrial connectors have become an indispensable part of modern electronic industry, with great application value and broad development space.

To ensure the stability and reliability of industrial connectors, there are several key points that need to be grasped:

1. When selecting a connector that meets the standards, it is necessary to confirm whether the volume, voltage, current, and other properties of the connector are suitable for the actual project needs, in order to avoid damage or performance degradation caused by selecting the wrong connector specifications.

2. Monitor the quality of connectors, and prioritize selecting manufacturers with rigorous quality control processes when purchasing connectors. The level of inspection and testing must be rigorous enough to ensure the quality of connectors.

3. Properly assemble and connect, and strictly follow the manufacturer's instructions during use to avoid connector damage or performance degradation caused by improper operation.

4. Regular maintenance and inspection of connectors are carried out to timely detect and handle abnormal situations, avoiding production stagnation and huge economic losses caused by connector problems.

5. By storing and managing in the correct way and using scientific storage methods, it is possible to effectively mitigate environmental impacts such as temperature, humidity, and vibration on the linker.

Only by correctly understanding and grasping these key points can we better utilize the functions of industrial connectors, improve production efficiency, and enhance product performance.